Thin-film lithium niobate (TFLN) is not just another material; it’s a beacon of innovation in the field of photonics, promising to transform how we interact with technology. At its core, TFLN is known for its robust electro-optic capabilities, pivotal in developing devices like modulators and frequency mixers. These devices are crucial for applications ranging from high-speed internet to advanced computing systems, offering unprecedented control over light. The unique properties of TFLN, such as its wide transparency window and strong nonlinear optical responses, allow it to manipulate light with precision and efficiency, marking a significant leap from traditional bulk lithium niobate.

Overcoming Fabrication Sensitivities

Despite its potential, the widespread adoption of TFLN technologies has been hindered by the challenges of fabrication. The precision required in the quasi-phase matching (QPM) of devices, a method used to enhance the interaction between light waves, is incredibly sensitive to even the smallest imperfections in material fabrication. This sensitivity has restricted the performance and yield of photonic devices, making it difficult to achieve the necessary consistency for commercial applications. The traditional fabrication method, which involves a sequence of poling before etching, often leads to discrepancies in device geometry, affecting the overall device efficiency and function.

A New Fabrication Technique

Enhancing Device Performance and Integration

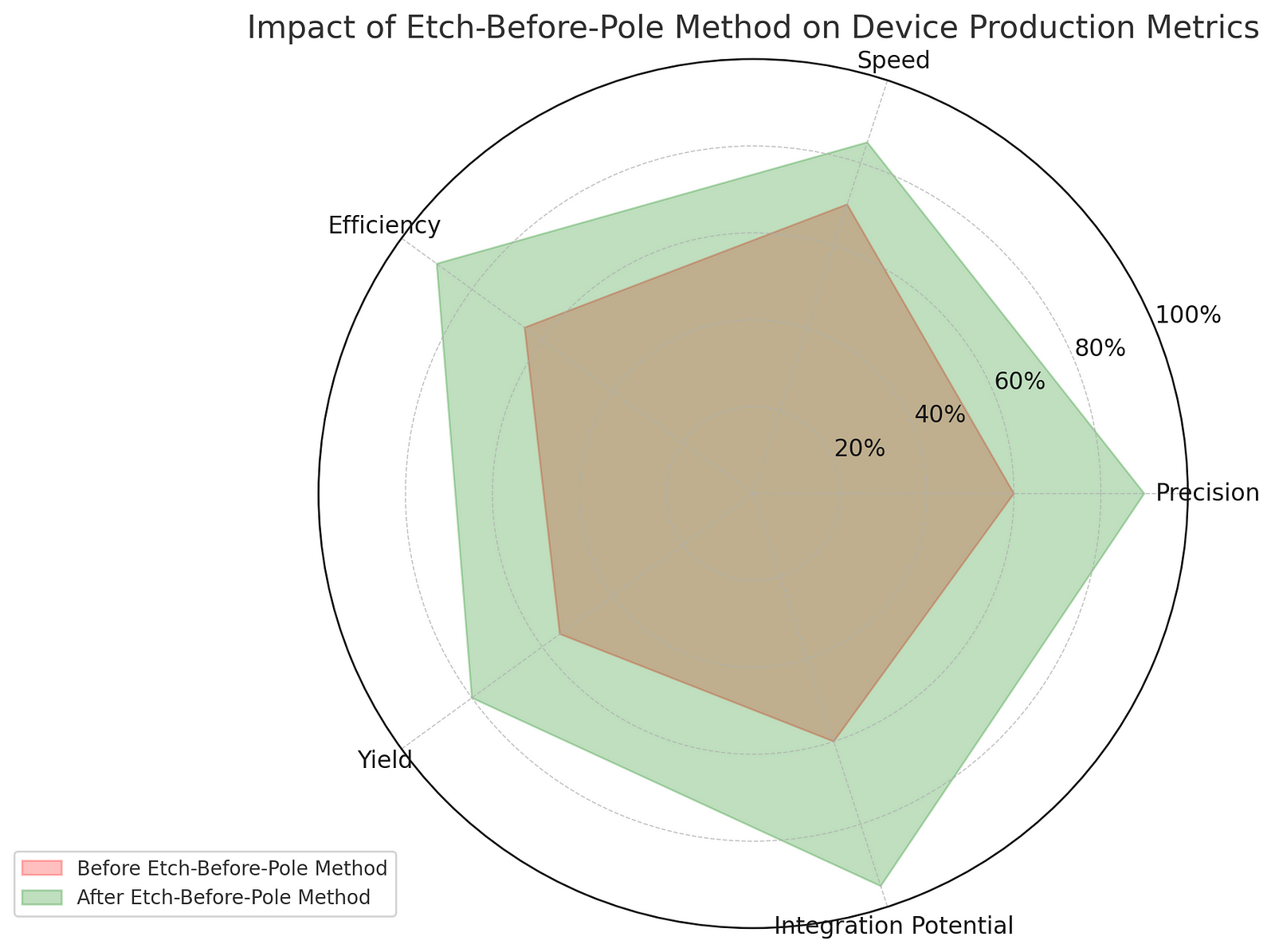

The practical impacts of this new method are profound. By increasing the yield and performance of TFLN-based devices, this technique paves the way for more complex and integrated photonic systems. Devices can now be produced with greater consistency, supporting advanced applications like quantum computing and integrated optical circuits. This could lead to more efficient and compact devices for a range of technologies, from telecommunications to sensors and beyond, marking a significant advancement in the scalability and functionality of photonic technologies.

Here is a radar chart that visually compares the performance metrics of thin-film lithium niobate devices before and after the adoption of the new etch-before-pole method. This graph will help you see just how much improvement the new method brings to various aspects of device production.

The Future Beckons

The implications of this technological evolution extend far into the future, heralding a new age of integrated photonics. With the enhanced capabilities and reliability provided by the etch-before-pole technique, TFLN can be more widely adopted in various high-tech applications, potentially transforming industries from healthcare to computing. The integration of TFLN into more complex systems could significantly advance our ability to process and transmit information, driving forward the boundaries of what’s possible with modern technology.

High Precision at the Nano Scale

TFLN devices can operate with precision down to nanometer scales. This level of accuracy is crucial for applications like quantum computing, where exact alignment of wavelengths influences the efficiency and reliability of quantum bits, or qubits.

Robustness Across a Wide Spectrum

TFLN exhibits transparency from near-ultraviolet to mid-infrared wavelengths. This wide range makes it incredibly versatile for various optical applications, from medical imaging devices to sensors that can detect a range of environmental changes.

Enhanced Speed and Efficiency

Devices made from TFLN can operate at speeds and efficiencies significantly greater than those made from bulk lithium niobate. This is due to the high optical confinement within TFLN’s thin films, which optimizes their interaction with light.

Scalability for Mass Production

The etch-before-pole method allows for the mass production of TFLN devices with consistent quality. This scalability is essential for commercializing the technology, making it a viable option for widespread use in consumer electronics and other industries.

Potential for Complex Photonic Circuits

The precision and reliability of TFLN devices make them ideal candidates for complex photonic circuits, which could revolutionize how data is processed and transmitted across networks, potentially leading to faster, more secure communication systems.

Envisioning a World Transformed by Thin-Film Lithium Niobate

As we peer into the technological horizon, the advancements in thin-film lithium niobate (TFLN) present not just evolutionary steps but revolutionary possibilities for the future of photonics. The novel etch-before-pole methodology reshapes the landscape of optical device fabrication, offering a beacon of efficiency and precision in an industry where both are paramount.

This innovative approach sidesteps the limitations of traditional methods by incorporating meticulous metrology before and after the etching process. As a result, it dramatically enhances the yield and performance of TFLN devices, ensuring that the vast majority meet stringent operational criteria without the need for extensive recalibrations.

The implications of these enhancements extend beyond mere improvements in device production. They promise to accelerate the integration of TFLN into sophisticated photonic circuits and systems, potentially catalyzing breakthroughs in quantum computing, telecommunications, and beyond. As this technology matures, it could lead to more compact, efficient, and faster optical devices, radically transforming our technological infrastructure and capabilities.

About Disruptive Concepts

https://www.disruptive-concepts.com/

Welcome to @Disruptive Concepts — your crystal ball into the future of technology. 🚀 Subscribe for new insight videos every Saturday!

Comments

Post a Comment